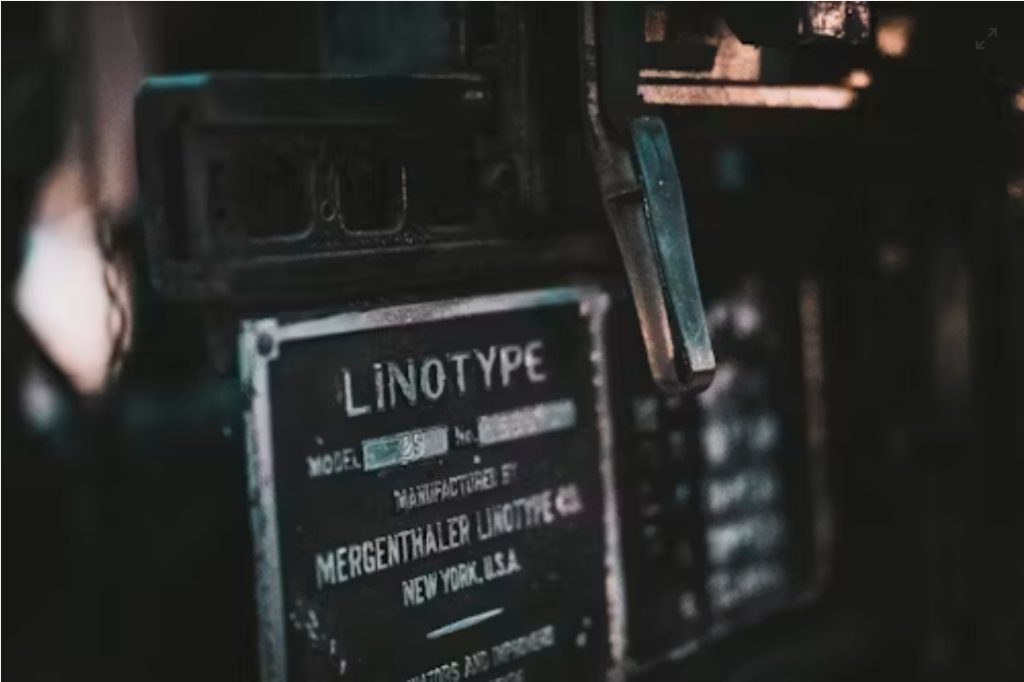

If you work with industrial equipment, you know that OEM machinery labels are the unsung heroes of operational efficiency and safety. These small but mighty identifiers provide critical information—from safety warnings to part numbers—that keeps your machines running smoothly and your team safe. But here’s the kicker: labels degrade over time. Faded text, peeling edges, or missing warnings can lead to costly downtime, compliance issues, or even workplace accidents.

In this ultimate cheat sheet, we’ll break down everything you need to know about maintaining OEM machinery labels like a pro. From cleaning hacks to replacement best practices, you’ll learn how to keep these essential markers in tip-top shape while boosting your equipment’s lifespan and compliance. Let’s dive in!

1. Why OEM Machinery Labels Matter More Than You Think

OEM machinery labels aren’t just stickers slapped onto equipment. They’re legally required, safety-critical tools that serve three key purposes:

- Compliance: Regulations like OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute) mandate clear, durable labels for hazard warnings, operating instructions, and certifications.

- Operational Efficiency: Labels help technicians quickly identify parts, troubleshoot issues, and follow maintenance protocols.

- Safety: Missing or damaged warnings can lead to accidents, injuries, or even fatalities.

Ignoring label maintenance is like driving a car with a cracked windshield—you’re gambling with risk.

Pro Tip: Use the keyword “OEM machinery labels” in your maintenance logs and safety audits to ensure visibility in documentation.

2. The #1 Rule of OEM Machinery Label Maintenance: Clean Smart, Not Hard

Dirt, grease, and grime are the arch-enemies of machinery labels. But scrubbing them aggressively can do more harm than good. Here’s how to clean labels without damaging them:

- Use Gentle Cleaners: Avoid harsh chemicals like acetone or bleach. Instead, opt for mild soapy water or isopropyl alcohol.

- Soft Cloths Only: Microfiber or lint-free cloths prevent scratches.

- Frequency Matters: Clean labels during routine equipment maintenance—think monthly or quarterly, depending on your environment.

Watch Out For: Steam cleaners or high-pressure washers. These can warp adhesive layers and cause peeling.

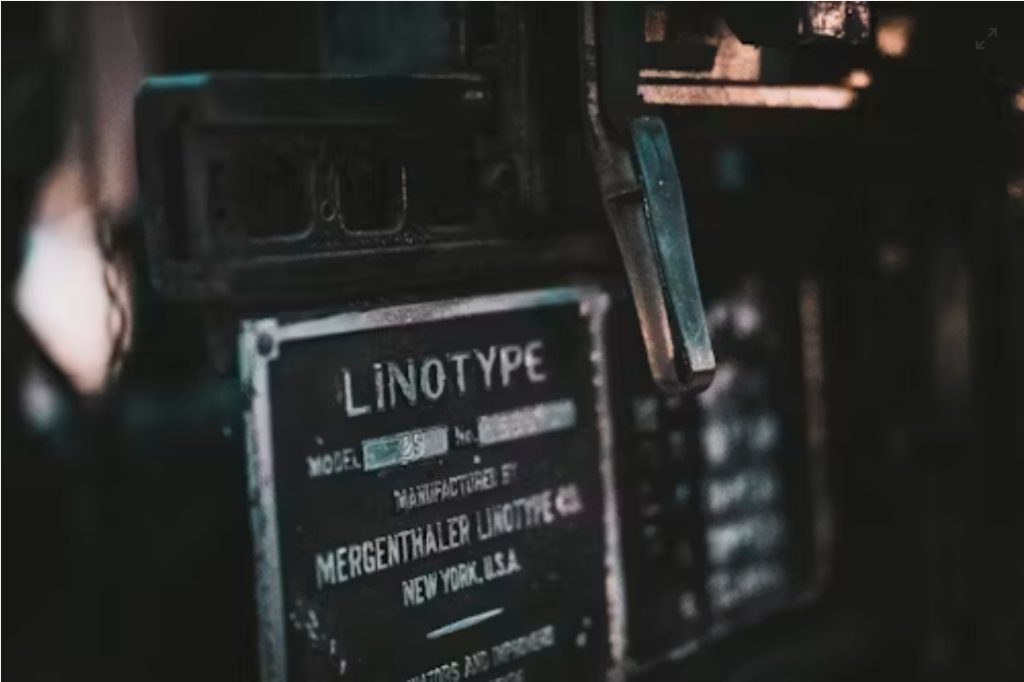

3. Spotting Early Damage: The Red Flags You Can’t Ignore

Even with careful cleaning, OEM machinery labels eventually wear out. Here’s how to spot trouble before it escalates:

- Fading: Sunlight, UV exposure, or chemical fumes can bleach text and symbols.

- Peeling Edges: Humidity or temperature swings weaken adhesives.

- Scratches or Tears: Physical abrasion from tools or debris.

- Outdated Information: Rebranded equipment? Updated safety protocols? Old labels become liabilities.

Quick Fix: Apply a clear laminate overlay to high-risk labels to extend their lifespan.

4. When to Replace OEM Machinery Labels (And How to Do It Right)

Replacing labels isn’t just about slapping on a new sticker. Follow these steps for a seamless process:

Step 1: Remove the Old Label

- Use a heat gun (on low) or adhesive remover to soften the glue.

- Gently scrape with a plastic tool—never metal!

Step 2: Prep the Surface

- Clean the area with isopropyl alcohol to remove residue.

- Ensure the surface is dry and dust-free.

Step 3: Apply the New Label

- Align carefully—crooked labels look unprofessional and can confuse operators.

- Use a squeegee to eliminate air bubbles.

Pro Tip: Order labels from your OEM provider to guarantee material quality and regulatory compliance.

5. Choosing the Right Label Material for Your Environment

Not all OEM machinery labels are created equal. Picking the wrong material is a recipe for frequent replacements. Match these options to your workspace:

- Polyester (PET): Resistant to chemicals, abrasion, and extreme temps. Ideal for factories or outdoor settings.

- Vinyl: Affordable and flexible, but less durable. Best for indoor, low-risk environments.

- Metal Tags: For ultra-harsh conditions (e.g., foundries or oil rigs).

Keyword Boost: Include “OEM machinery labels” in purchase orders to ensure vendors understand your specs.

6. Avoiding Common Label Maintenance Mistakes

Even seasoned pros slip up. Steer clear of these pitfalls:

- Using Generic Labels: Off-the-shelf stickers often lack OEM-grade adhesives or materials.

- Ignoring Regulatory Updates: Safety standards evolve. Regularly audit labels for compliance.

- Overlooking Barcodes/QR Codes: Modern labels often include scannable codes for inventory tracking. Keep them readable!

Real-World Example: A Midwest auto plant failed to update lockout/tagout labels after a regulation change, resulting in a $12K OSHA fine. Don’t be that guy.

7. Long-Term Benefits of Proactive Label Maintenance

Investing time in OEM machinery labels pays off in spades:

- Reduced Downtime: Clear labels = faster repairs and fewer errors.

- Lower Compliance Risks: Avoid fines or legal headaches.

- Enhanced Safety Culture: Visible warnings foster a mindful workplace.

Stats Don’t Lie: Companies with robust label systems report 30% fewer equipment-related incidents.

Final Thoughts: Label Maintenance is a Team Effort

Maintaining OEM machinery labels isn’t a one-person job. Train your team to:

- Report damaged labels immediately.

- Follow cleaning/replacement protocols.

- Stay updated on industry regulations.

Remember, labels are your equipment’s “voice.” Keep them loud, clear, and compliant.

Action Step: Conduct a label audit this week. Replace any worn-out OEM machinery labels, and document the process for future reference.

By sticking to this cheat sheet (pun intended), you’ll keep your machines—and your team—running like a well-oiled machine.