In industrial, commercial, and institutional applications, nameplates serve critical functions ranging from equipment identification to safety compliance and brand representation. Among various material options available for nameplate manufacturing, stainless steel has emerged as the superior choice across multiple industries. This article examines the technical and practical advantages that make stainless steel nameplates outperform alternatives such as aluminum, brass, plastic, and other metals in demanding environments.

Durability and Longevity

Stainless steel nameplates demonstrate exceptional durability compared to other materials. The inherent strength of stainless steel alloys provides resistance against physical impacts, abrasion, and deformation that commonly damage or degrade nameplates made from softer materials. Unlike plastic nameplates that become brittle over time or aluminum plates that dent easily, stainless steel maintains structural integrity throughout extended service life.

The longevity of stainless steel nameplates stems from their metallurgical properties. Austenitic stainless steels (300 series) particularly offer excellent corrosion resistance due to their chromium content (minimum 10.5%), which forms a passive oxide layer that self-repairs when damaged. This characteristic ensures that stainless steel nameplates remain legible and presentable for decades, even in harsh outdoor or industrial environments where other materials would deteriorate rapidly.

Corrosion Resistance

Superior corrosion resistance represents one of stainless steel's most significant advantages over alternative nameplate materials. While aluminum develops oxidation and brass tarnishes over time, stainless steel resists multiple forms of corrosion:

1. Atmospheric Corrosion: Performs exceptionally in coastal, urban, and industrial atmospheres containing salt, moisture, and pollutants.

2. Galvanic Corrosion: When properly selected and installed, stainless steel minimizes galvanic reactions with dissimilar metals.

3. Pitting and Crevice Corrosion: Higher-grade stainless steels (316 and above) resist these localized corrosion forms common in chloride-rich environments.

4. Stress Corrosion Cracking: Appropriate alloy selection prevents this failure mode that affects some metals under tension.

This comprehensive corrosion resistance makes stainless steel ideal for applications in chemical plants, marine environments, food processing facilities, and medical institutions where sanitation and material stability are paramount.

Temperature Tolerance

Stainless steel nameplates maintain performance across extreme temperature ranges that would compromise other materials. They withstand continuous exposure from cryogenic temperatures (-200°C/-328°F) up to approximately 870°C (1600°F) for standard grades, with specialized alloys capable of higher thresholds. This thermal stability proves crucial for:

- Industrial equipment operating at elevated temperatures

- Outdoor applications subject to seasonal variations

- Laboratory and cryogenic equipment identification

- Components near heat sources where plastics would melt or deform

Unlike plastic nameplates that warp or aluminum plates that experience significant thermal expansion, stainless steel provides dimensional stability across temperature fluctuations.

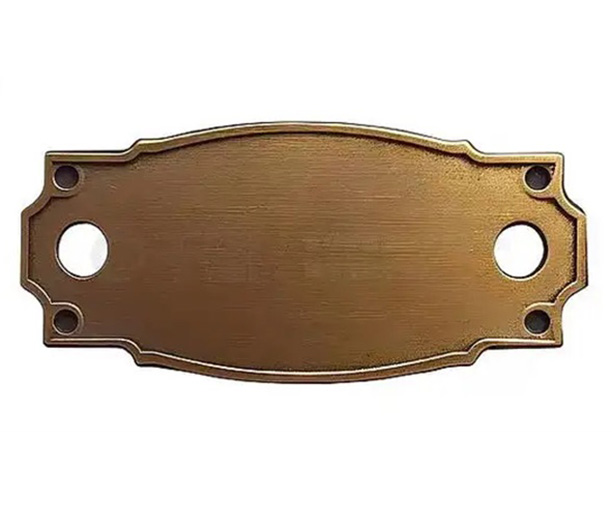

Aesthetic Permanence

The visual appeal of stainless steel nameplates remains consistent over time, unlike materials that fade, discolor, or require frequent maintenance. Key aesthetic advantages include:

1. Surface Finish Options: Available in brushed, polished, matte, or textured finishes to match design requirements.

2. Color Stability: Unlike painted or anodized surfaces, stainless steel doesn't require color coatings that chip or fade.

3. Legibility Maintenance: Engraved or etched markings on stainless steel resist wear better than printed labels or stamped softer metals.

4. Professional Appearance: Projects quality and permanence appropriate for corporate, institutional, and high-end applications.

For branding applications where image consistency matters, stainless steel nameplates ensure logos and text remain clearly visible without periodic replacement or refurbishment.

Environmental Resistance

Stainless steel nameplates demonstrate unparalleled resistance to environmental factors:

1. UV Radiation: Unlike plastics that degrade under sunlight, stainless steel remains unaffected by UV exposure.

2. Moisture and Humidity: Performs in 100% relative humidity conditions where other metals corrode.

3. Chemical Exposure: Resists acids, alkalis, solvents, and cleaning agents that damage alternative materials.

4. Biological Growth: Non-porous surface inhibits mold, mildew, and bacterial colonization common on organic materials.

This comprehensive environmental resistance makes stainless steel the preferred choice for outdoor signage, marine applications, pharmaceutical facilities, and food processing plants with stringent hygiene requirements.

Safety and Compliance

In regulated industries, stainless steel nameplates facilitate compliance with safety and identification standards:

1. Non-Combustibility: Meets fire safety codes where plastic nameplates would be prohibited.

2. Non-Toxic: Suitable for food contact and medical applications without leaching concerns.

3. Permanent Marking: Complies with equipment identification standards requiring indelible markings.

4. Hazardous Area Certification: Available in versions approved for explosive atmospheres.

The material's inherent properties reduce liability concerns associated with nameplate failure in critical applications.

Cost-Effectiveness Over Lifecycle

While stainless steel nameplates may have higher initial material costs than some alternatives, their lifecycle cost proves superior due to:

1. Eliminated Replacement Costs: Lasts decades versus years for inferior materials.

2. Reduced Maintenance: Doesn't require cleaning, repainting, or refinishing.

3. Labor Savings: Installation remains permanent without need for adjustments or reattachment.

4. Asset Protection: Prevents misidentification that could lead to equipment misuse or safety incidents.

When calculated over typical service life, stainless steel nameplates often demonstrate the lowest total cost of ownership among all material options.

Manufacturing Flexibility

Modern fabrication techniques allow stainless steel nameplates to accommodate diverse design requirements:

1. Precision Marking: Laser etching, chemical engraving, and dot peening create permanent, high-resolution markings.

2. Custom Shapes: Laser cutting and waterjet technology enable complex geometries.

3. Attachment Options: Weldable, riveted, or adhesive-mounted configurations available.

4. Multi-Layer Construction: Can incorporate insulating layers for electrical applications.

This manufacturing versatility ensures stainless steel can meet specialized application needs that constrain other materials.

Sustainability Considerations

Stainless steel offers environmental advantages that align with sustainable practices:

1. 100% Recyclable: Maintains material value at end of service life.

2. Long Service Life: Reduces resource consumption through extended usability.

3. Low Environmental Impact: Production processes have improved significantly in energy efficiency.

4. Non-Toxic Decomposition: Doesn't release harmful substances if improperly disposed.

These characteristics make stainless steel nameplates responsible choices for environmentally conscious organizations.

Conclusion

The comprehensive advantages of stainless steel nameplates—encompassing durability, corrosion resistance, temperature tolerance, aesthetic permanence, environmental resilience, safety compliance, lifecycle economics, manufacturing flexibility, and sustainability—establish their superior performance across virtually all demanding applications. While alternative materials may serve adequately in limited, controlled environments, stainless steel consistently delivers reliable performance where nameplate integrity matters most. This combination of technical merits explains why stainless steel remains the material of choice for critical identification, branding, and compliance applications across industries worldwide.